Staffing boom in the workshop

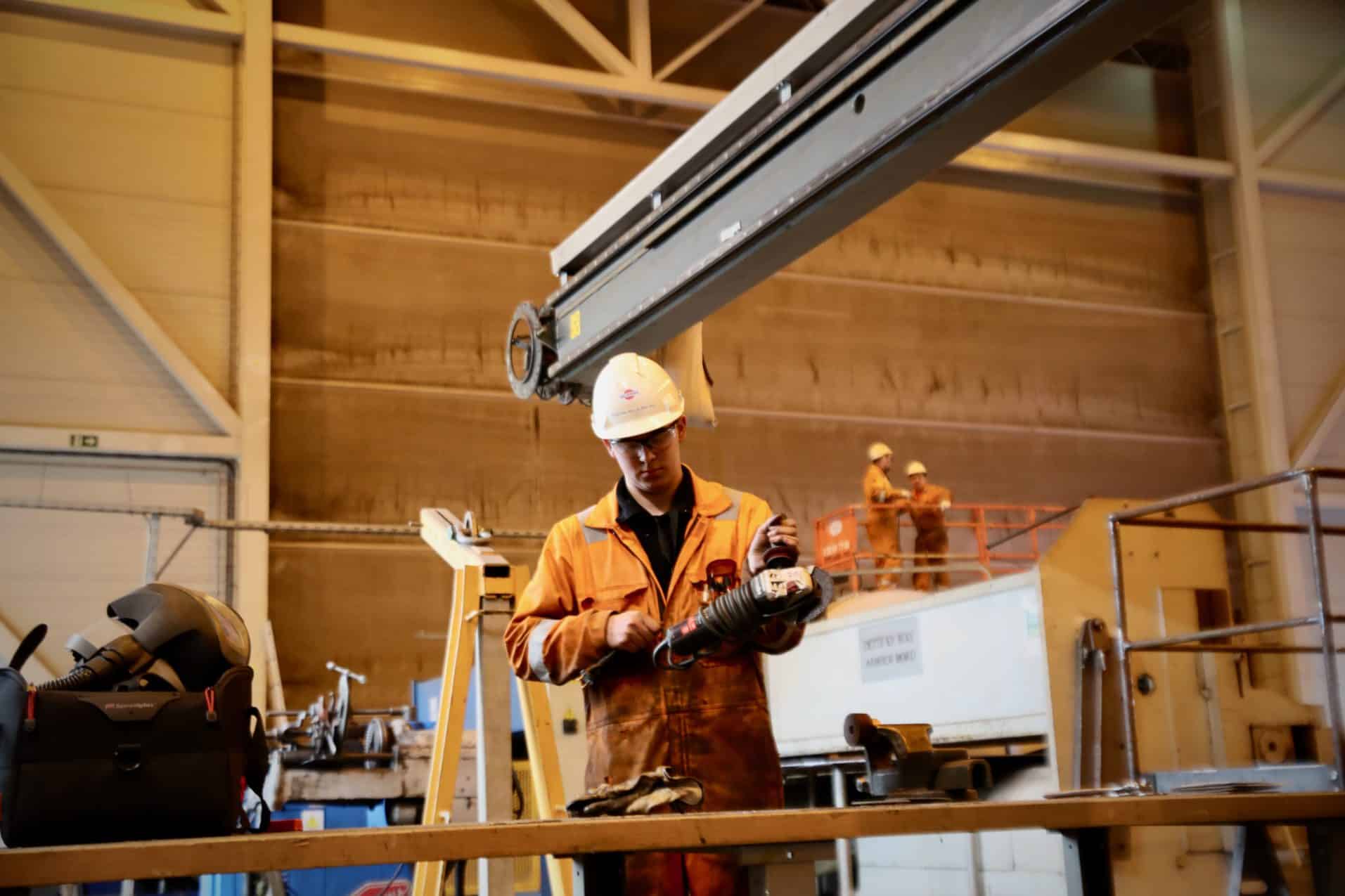

With 12 new employees so far this year, the workshop has had its capacity strengthened.

Increased need for mechanical personnel available for travel assignments is the reason for the expansion of the staff.

- In order to be able to make upgrades on pressure equipment in the field, it is crucial that the employees work daily with similar equipment. The workshop personnel must be trained and competent to be able to go on assignments outside the workshop, says CEO, Frode Olsen.

TOGETHER now has 27 men based in the workshop. The range of expertise is large - from industrial mechanics, welders and sheet metal workers to plumbers, insulators and fitters. Many have solid travel experience, both onshore and offshore.

12 NEW MEN: Head of fabrication, John Vester Nielsen, has got 12 new employees in the workshop.

12 NEW MEN: Head of fabrication, John Vester Nielsen, has got 12 new employees in the workshop.

- These are skilled people, but in our specialization there is a need for formal competence with welding certification and courses. This is necessary to be able to work that requires high quality and professional skill, says head of fabrication, John Vester Nielsen.

Tratec Halvorsen has specialist expertise in new production and modifications to equipment that is charged for pressure and temperature, as well as projects with a high degree of accuracy in execution, implementation and documentation.

THE WORKSHOP EMPLOYEES works with PED-approved equipment, which means that the equipment is classified according to the directive for pressure-exposed equipment.

2020 has been a year of much activity. Nielsen and his colleagues have also produced pig launchers, pipe coils, boilers, tanks, skids with filter tanks, fire protection equipment, aluminum filters, steel structures, knock-out drums and platform expansion for lifeboats.

- We are a nice bunch in the workshop. Here are multidisciplinary workers from 18 to 62 years, says Nielsen.

- No women?

- No, but our warehouse manager is a woman. She is also a former welder, says Nielsen, who describes the working environment as safe and good.

In connection with recent resource needs and challenges with foreign labor, she has also practiced in a workshop as a welder.

NEW APPRENTICE: Kristian Helleland started as an industrial mechanic apprentice at the workshop earlier this year.

NEW APPRENTICE: Kristian Helleland started as an industrial mechanic apprentice at the workshop earlier this year.

- In Tratec Halvorsen, everyone contributes in the areas they master when necessary. This is how we stay capable of delivery in demanding times, says Frode Olsen.

KORONAPANDEMIEN has left its mark on most Norwegian workplaces. The workshop at Tratec Halvorsen is no exception.

- The company has introduced strict measures internally and externally to avoid infection. But I think we can handle this very seriously and I understand that everyone has a good understanding that this must be taken seriously, says Nielsen.

COMPETENCE REQUIREMENTS: The workshop personnel must be trained and competent to be able to go on assignments outside the workshop, says CEO, Frode Olsen.

COMPETENCE REQUIREMENTS: The workshop personnel must be trained and competent to be able to go on assignments outside the workshop, says CEO, Frode Olsen.