With 90 kilos in each weld

The "Pig Receiver" who is going to the North Sea is among the largest that Tratec Halvorsen has produced in recent times.

"These are difficult things," says manager of fabrication, John Vester Nielsen, enthusiastically.

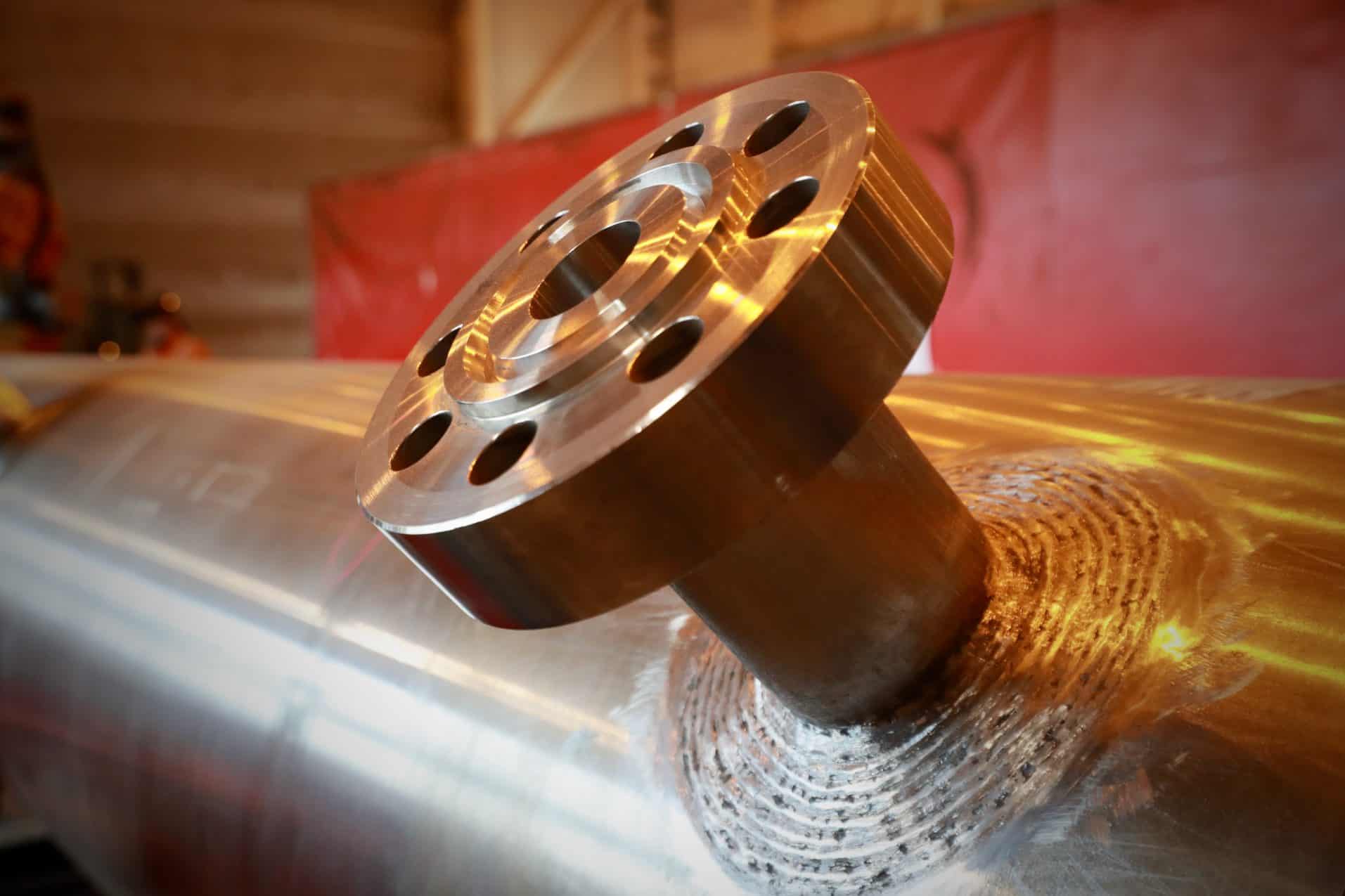

Behind him, Rafal Michalek is welding a steel pipe with a diameter of 800 millimeters and at its thickest 120 millimeters.

WHEN IT IS When welded together, the "Pig Receiver" will weigh 12 tonnes.

- Each joint has 90 kg of weld added. Pure welding technology, the job is demanding, says Nielsen.

The "Pig Receiver" must be installed on the Norwegian shelf.

- WHAT IS especially with this "Pig Receiver" is that it can withstand very high pressure. When we finish the annealing and painting job, it is transported westwards by car, says Kjell Vidar Netland, head of pressurized equipment.

In the oil industry, "pigging" is a term for a pipe cleaning process. Brushes are inserted into the tube and pushed along the pipeline to clean out rust, wax and debris. The scratching noise that occurs in the process can be reminiscent of a howling pig - hence the name "pigging".

The brush is placed in a "pig launcher", which is a sort of launching station, and then pushed down into the tube until it reaches the receiving station - the so-called "pig receiver".