Upgrading exhaust pipes for Åsgård B

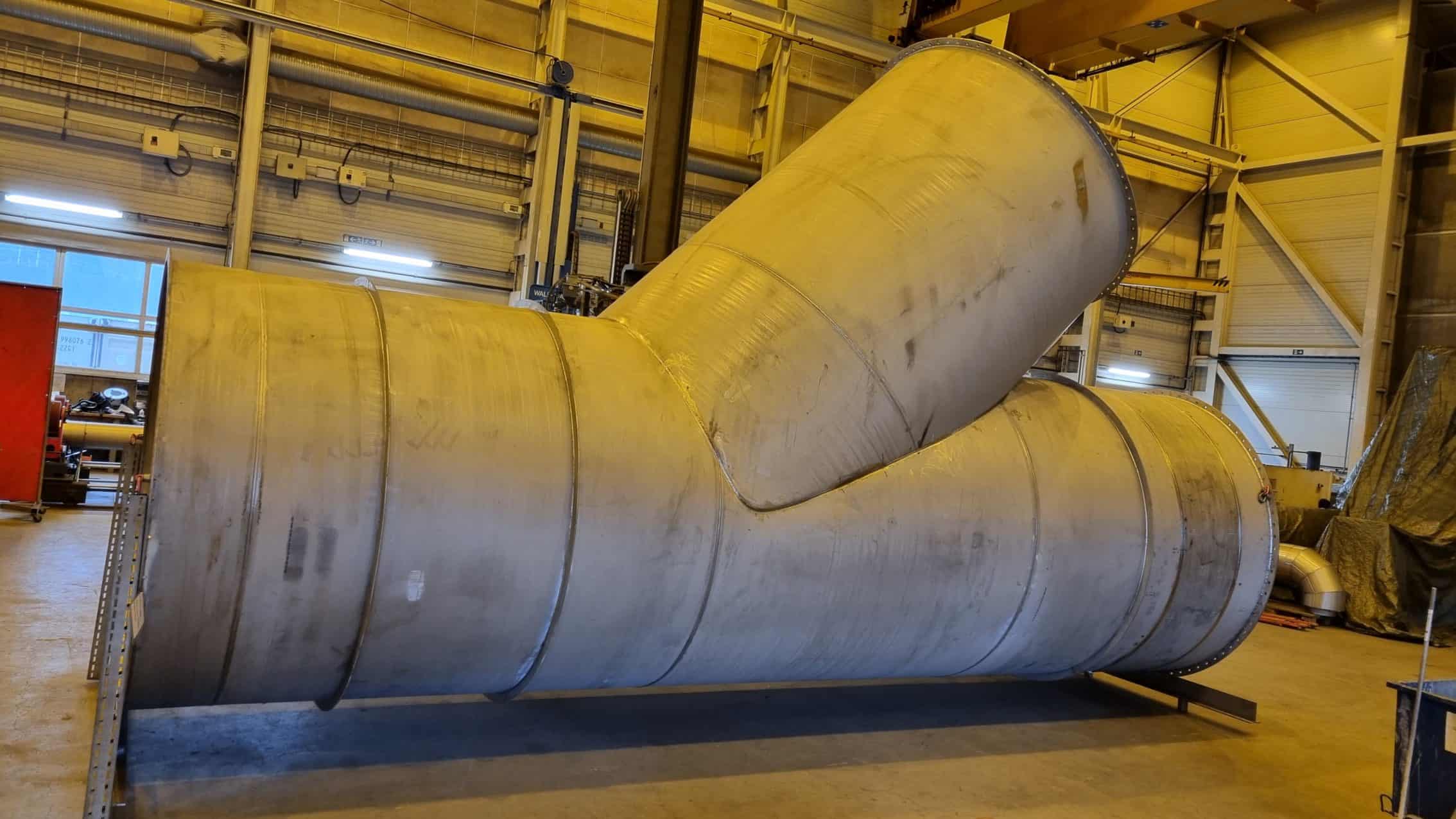

Here, the new parts are welded onto one of two identical exhaust pipes in place. Over 2,000 welding hours go into improvements in the project.

- The pipes are to be used in an installation at Åsgård B, but have been stored with us for some time awaiting the start of the project out there, says project manager Stanley Rafoss.

When a construction error was discovered on a similar job, the Åsgård pipes had to be taken back into the workshop at Øyesletta and upgraded.

- We had to cut the pipes in half and insert a new segment, says Rafoss.

The exhaust pipes have an internal diameter of 2.4 meters and tower well in the workshop hall.

- When we have finished the upgrade, the pipes will be transported into the warehouse we have on site until the customer is ready to receive the entire installation package, says Rafoss.

Tratec Halvorsen's client is Aker Solutions, while the end customer is Equinor.