Gives the process module an increased lifespan

After extensive engineering and upgrading, the process module is ready for 25 new years in offshore service.

Text and photo: Sveinung W. Jensen, Tellus Communications

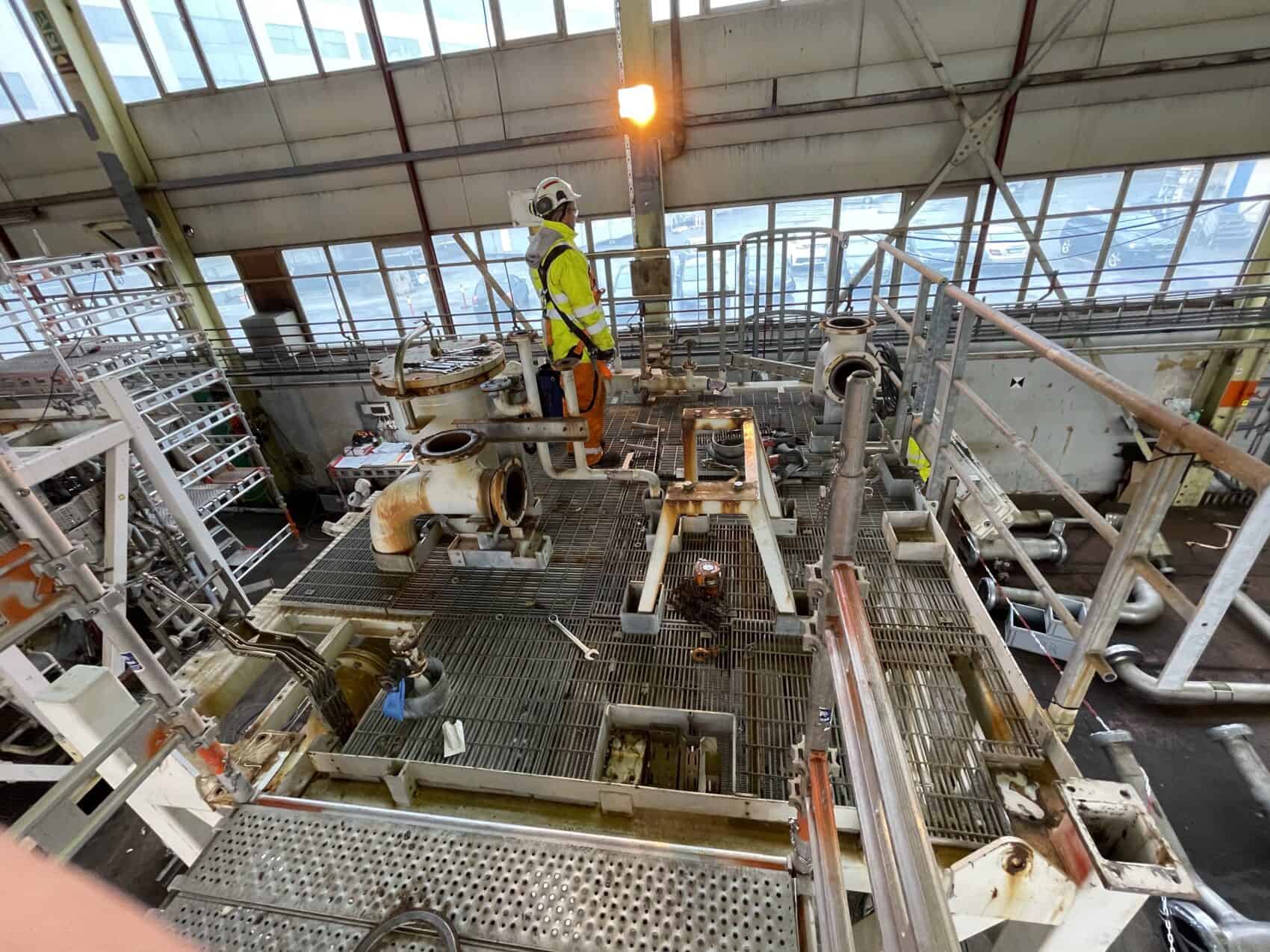

- We are probably talking about around 1,000 parts in total, smiles Stanley Rafoss, who leads the work to extend the life of the 28.5-tonne ski.

The project is part of the upgrade of an installation in the North Sea.

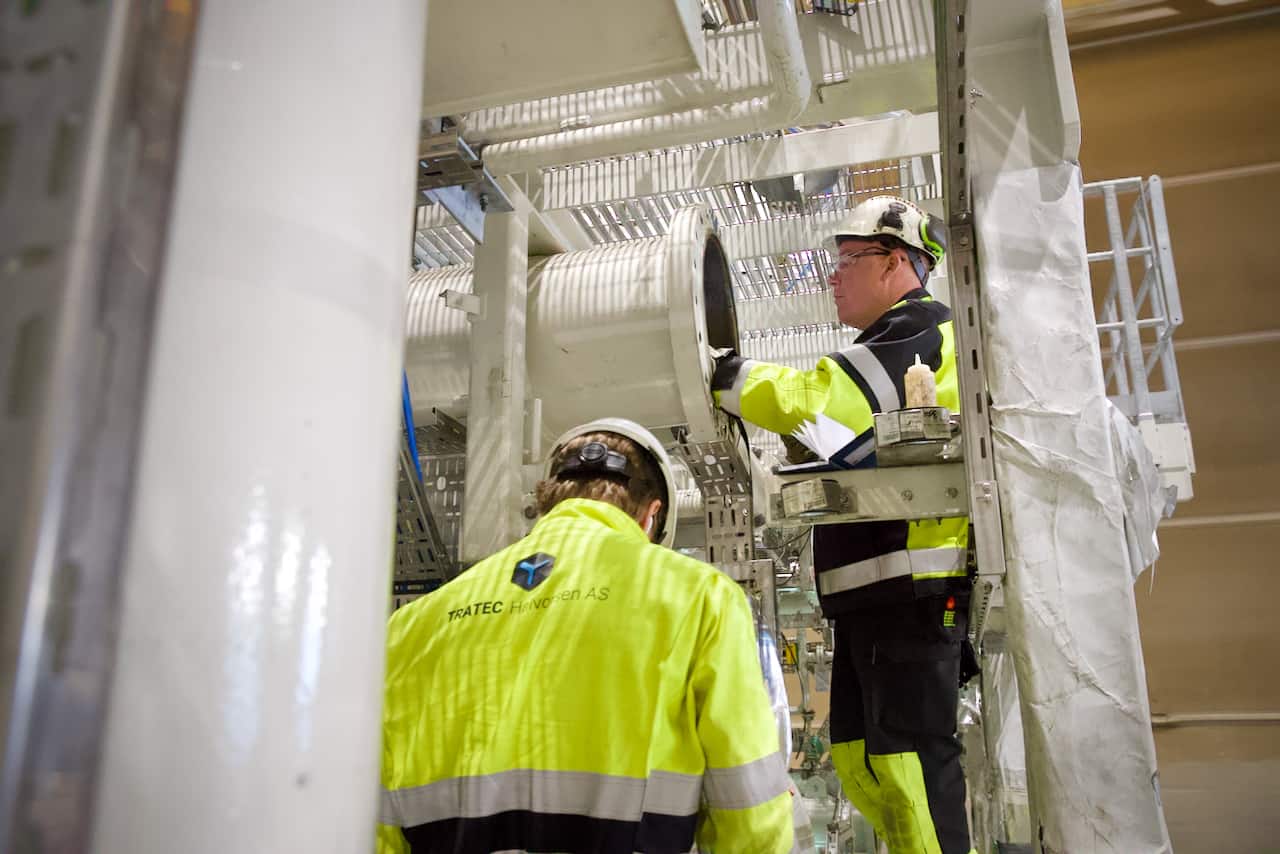

IT'S CROWDING OFF workers around the white structure, where it stands and shines inside Tratec Halvorsen's workshop. Cables are pulled, tested, measured and painted.

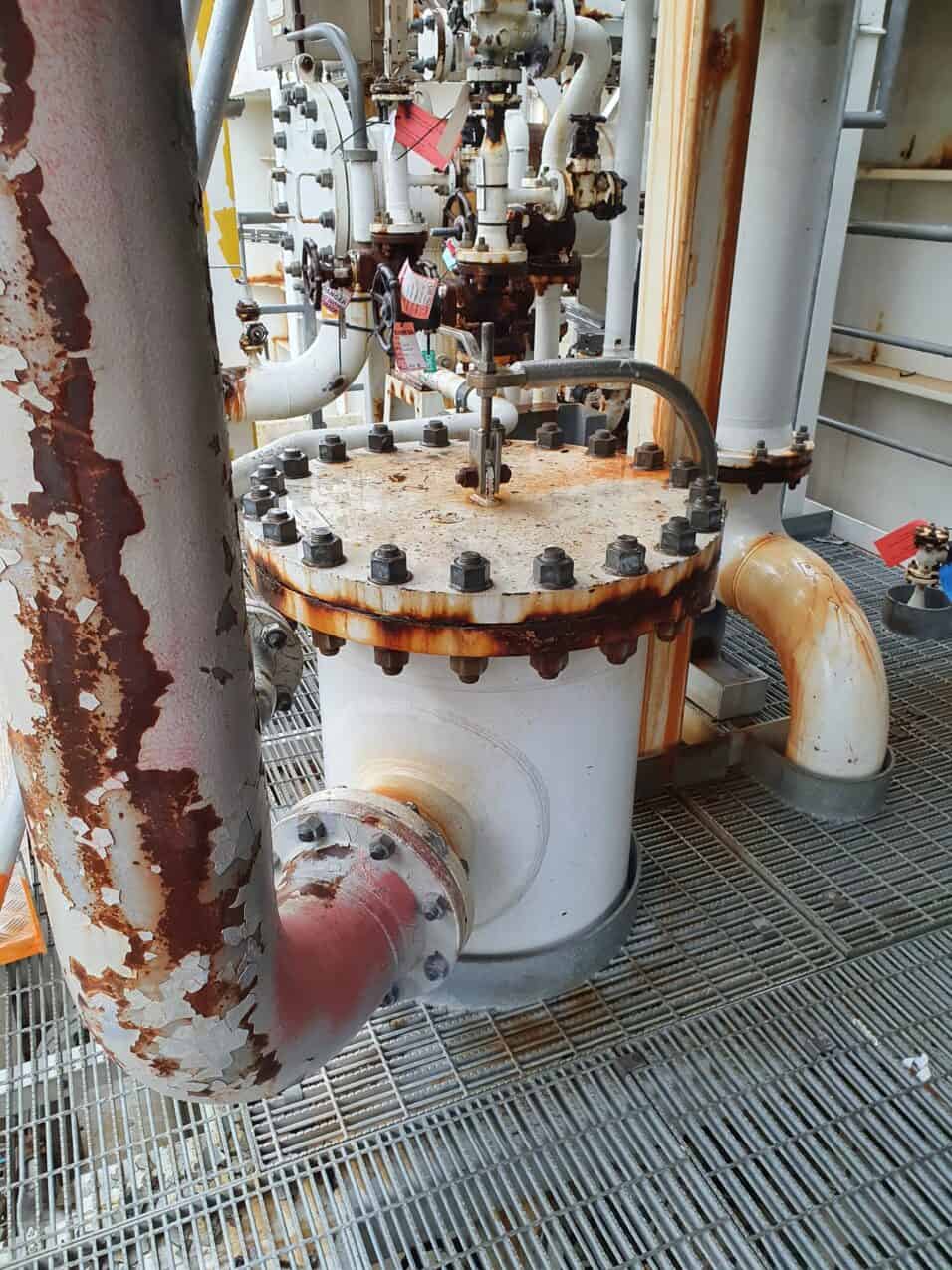

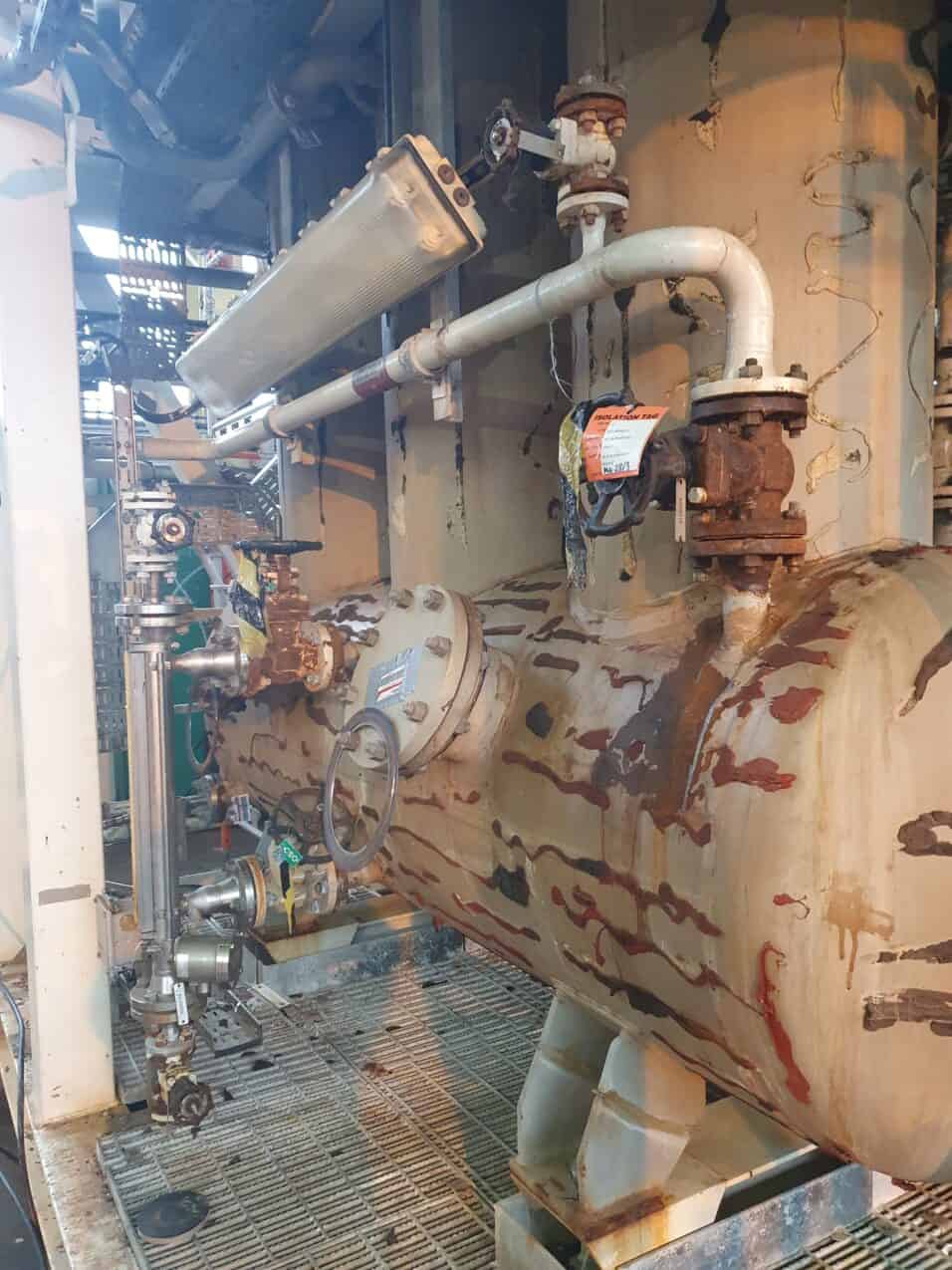

- The process module was dismantled from the Jotun ship last winter and moved to our facility in Kvinesdal. All parts have been dismantled, marked and prepared for further comprehensive inspection and testing, says Rafoss.

After inspection of all parts, detail engineering is carried out - which is more extensive than building a new process module.

- In this process, it is important to have a lot of expertise and experienced personnel, and a close dialogue with the authorities' approval body, says Rafoss.

IN THIS PHASE the available reports and data are calculated and assessed. In this way, the lifetime of the components to be reassembled is documented and extended.

- The fully assembled module will satisfy the same requirements and qualities as a completely new corresponding module, states Rafoss.

The ski is eight meters long, four meters wide and seven meters high. The structural frame itself has been in the workshop since February.

GRADUALLY HAVE the parts have been screwed and welded back into place. Not insignificant engineering work has been done.

- This is a big job. A lot has to be planned. All pipes are fixed. Where we have been missing pipes, we have made new ones. Work is now being done to get the valves in place. All valves are new, manufactured in Italy. The old ones are used as dummies, so that the assembly of pipes could start this summer, says Rafoss.

The project has mostly gone as planned, with the exception of some deliveries.

- The world is on its heels. There have been delays on some of the parts, says Rafoss.

FOR TRATEC Halvorsen fits the project perfectly into the company's increased focus on "lifetime extension" of boilers, pressure vessels and systems for water heat recovery and water treatment.

- The vast majority of the module is reused. The project is therefore a good example of green and sustainable production. In addition, the costs of upgrading the old module are significantly lower than if the customer were to build a completely new module, says Rafoss.

Planned shipping is in November. The ski is then transported down to the quay and from there on by boat to the customer.