Process module ready for Jotun FPSO

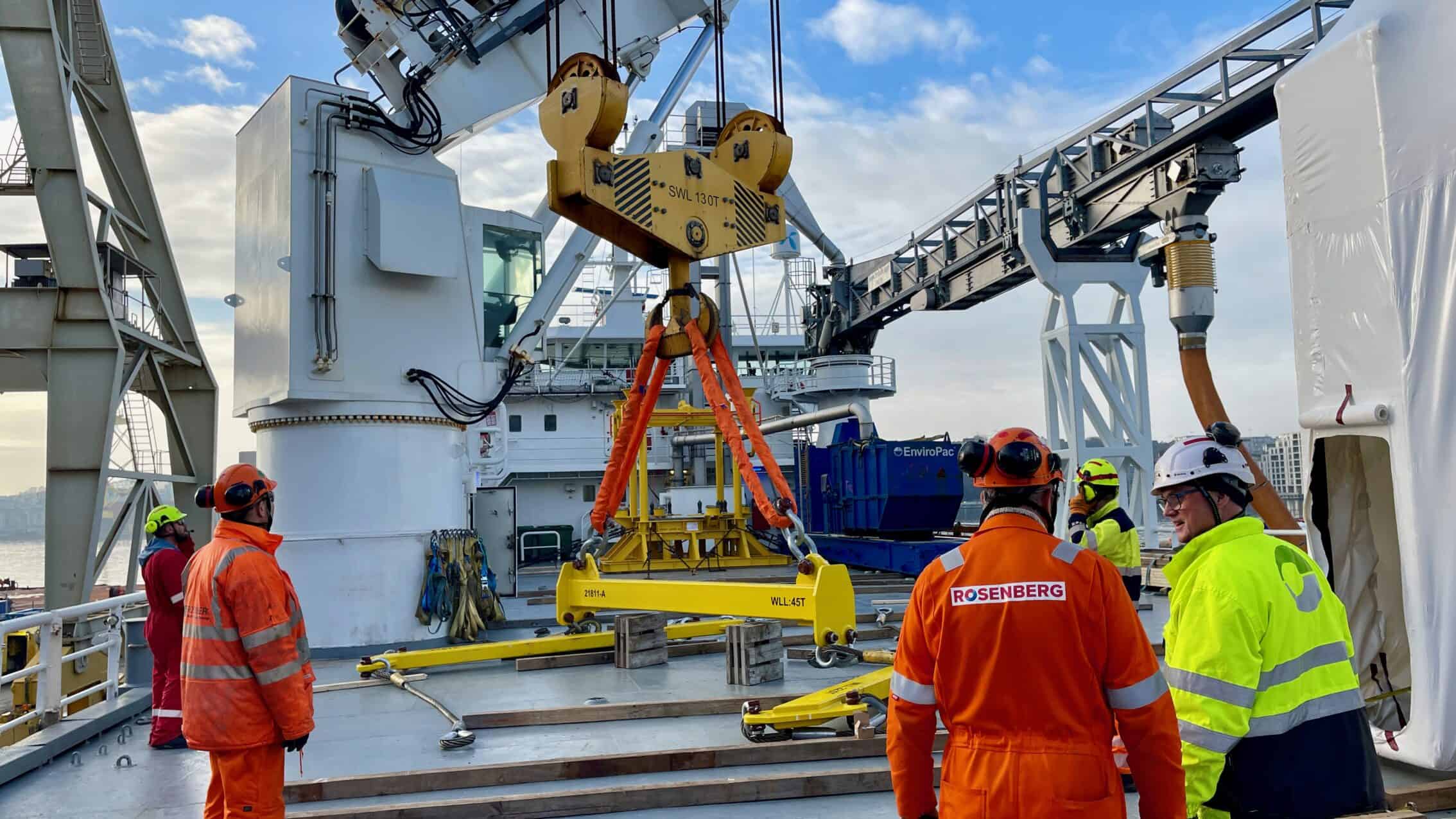

Here, the 40.3-tonne process module is lifted on board the Jotun FPSO production ship.

Text: Sveinung W. Jensen, Tellus Communications

There is hectic activity in the workshop in Kvinesdal. For over a year, project managers, engineers, fitters, electricians, welders and others have worked on the eight-metre-long, four-metre-wide and seven-metre-high steel colossus. The final touches are now being put on the work.

- Some of the parts at the very top had to be dismantled, packed and sent in loose parts. There was simply not enough ceiling height in the workshop when the module had to be lifted onto the car, says head of fabrication, John Vester Nielsen.

AFTER HAVING been driven a few hundred meters away to the quay, the finished module is transported by boat to Stavanger.

The project is part of the upgrade of the Jotun FPSO production vessel, which is located at the Worley Rosenberg Stavanger shipyard.

THE PROCESS MODULE was dismantled from the ship and moved to the workshop in Kvinesdal. Around 1,000 parts have been dismantled, marked and prepared for further extensive inspection and testing.

- It is an extensive engineering job, says Stanley Rafoss, who leads the work on extending the life of the module.

All parts were thoroughly inspected before detailed engineering was carried out.

- Here it is important to have a lot of expertise and experienced personnel, and a close dialogue with the authorities' approval body, says Rafoss.

IN THIS PHASE the available reports and data are calculated and assessed. In this way, the lifetime of the components to be reassembled is documented and extended.

- The fully assembled module is now ready for another 25 years in offshore service. It will satisfy the same requirements and qualities as a completely new corresponding module, says Rafoss.

THE PROJECT IS part of a delivery to the Lifetime Extension project of the Jotun FPSO. Tratec Halvorsen is responsible for extending the service life of all pressurized tanks and heat exchangers in the process plant on board.

- This is a good example of green and sustainable production. In addition, the costs of upgrading the old module are significantly lower than if the customer were to build a completely new module, says Rafoss.